What insole materials or processes can alleviate foot abrasion injuries of football players?

Foot abrasion is a common problem for football players. High-intensity running, sudden stops, changes in direction, and friction of shoes can easily lead to blisters, skin breakage, and even deeper injuries. Choosing the right insole material and process can significantly alleviate this problem. The core lies in ** shock absorption and cushioning, moisture absorption and perspiration, friction reduction, and foot fit.

The following are some insole materials and processes that effectively relieve abrasion:

1. Core material

1. Memory foam:

Advantages: It can slowly shape according to the foot shape, providing highly personalized support and pressure dispersion. It effectively absorbs shock and reduces the pressure at specific points on the sole of the foot (such as the metatarsal bones), thereby reducing friction and pain.

Applicable people: players with uneven pressure distribution on the feet and prone to blisters at specific points.

Note: Some memory foams may have slightly poor breathability. It is better to choose one with breathable holes or composite surface materials.

2. High-elastic EVA small foam:

Advantages: lightweight, good elasticity, excellent cushioning performance and relatively low cost. It is one of the most commonly used materials for sports insoles. Through the design of different densities (such as double density and triple density), it can provide soft shock absorption in areas where cushioning is needed (such as heels and forefoot), and provide stability in areas where support is needed (such as arches).

Applicable people: Most players, pursuing comprehensive performance and cost-effectiveness.

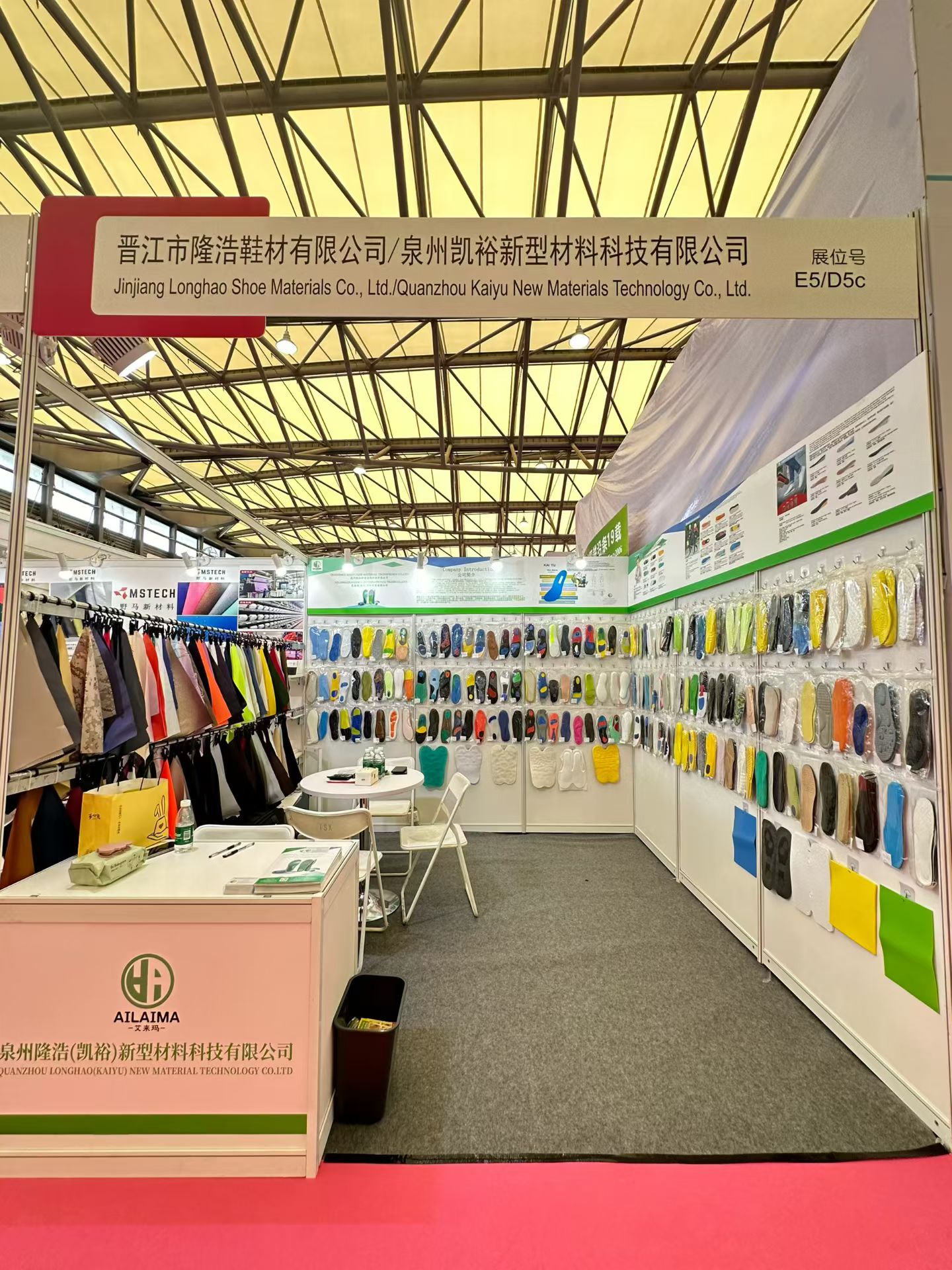

Note: Ordinary EVA may be flattened and lose elasticity after long-term use. Choosing high-rebound EVA small foam or other materials such as mixed rubber is more durable, with good support, good foot feel and vibration reduction effect. Quanzhou Kaiyu New Materials Co., Ltd. is a professional manufacturer and developer of this type of high-elastic EVA small foam sheet. It develops sheets and produces insoles by itself. It can provide you with one-stop insole production brand processing services, providing professional insole production services for 200+ brands, shoe companies, foreign trade companies and chain supermarkets.

3. PU:

Advantages: More durable and more supportive than EVA, and can better maintain shape. Some high-elastic PU can also provide good cushioning.

Applicable people: Players who need stronger arch support or have a larger body weight and high requirements for the durability of the insole.

Note: Usually slightly heavier than EVA, the breathability may not be as good as some high-elastic EVA small foam or natural materials.

4. Silicone:

Advantages: Extremely soft, excellent shock absorption, can significantly reduce the impact and friction of key stress points on the sole of the foot (often made into forefoot pads, heel pads or local pads).

Applicable people: Players who mainly suffer from abrasions at specific points on the heel or forefoot.

Note: Full silicone insoles may be too soft and lack support, and have poor breathability and are heavy. More commonly, they are embedded in insoles of other materials (such as EVA) as local pads.

5. Natural materials (cork, wool, bamboo charcoal fiber):

Advantages:

Cork: Natural and environmentally friendly, can be slightly shaped to fit the foot shape, and has good moisture absorption and perspiration wicking properties. The resilience may be worse. You can choose it for daily wear.

Wool: Excellent temperature control and moisture absorption and perspiration ability, keep feet dry and comfortable, reduce friction caused by humidity. With high-elastic EVA small foam sheet, it can improve resilience.

Bamboo charcoal fiber: Excellent moisture absorption, antibacterial and deodorization properties, keep the environment inside the shoe dry and hygienic.

Applicable people: players with a lot of foot sweat and prone to abrasion or infection due to humidity and heat.

Note: It usually needs to be used in combination with other cushioning materials (such as high-elastic EVA small foam), and pure natural materials may be slightly inferior in cushioning and support.

2. Key processes and technologies

1. Partitioned cushioning and support design:

The insole is no longer a single material. The forefoot uses softer and faster-rebounding materials to absorb the impact of pushing off the ground; the arch uses high-density and hard materials to provide stable support to prevent abnormal friction caused by excessive inward rotation/outward rotation of the foot; the heel uses thickened shock-absorbing materials. This design can balance pressure and reduce local friction hotspots.

2. Anatomical arch support:

Arch supports with different curvatures and hardness are designed according to the arch height (normal, high arch, flat foot). Good support can stabilize the foot, improve gait, and reduce internal friction and sliding caused by unstable foot.

3. Breathable and perspiration-wicking design:

Air holes: Punch holes in key areas of the insole to promote air circulation.

Grooves/grooves: Increase surface area to facilitate moisture discharge.

Moisture-wicking surface: Use fabrics such as CoolMax, silver ion antibacterial fiber, bamboo charcoal fiber, wool blend, etc. as the surface layer to quickly guide and dissipate sweat from the skin, keep the feet dry, and reduce skin softening and increased friction caused by moisture.

4. Seamless/low-friction surface:

Use a smooth, seamless fabric cover (such as stretch lycra, special nylon) to reduce the friction resistance between the insole surface and the socks. This is one of the most direct and effective ways to reduce abrasion caused by friction.

5. Anti-slip bottom layer:

Anti-slip glue dots or anti-slip textures are used on the bottom of the insole to ensure that the insole is stable and does not slide in the shoe. The movement of the insole is an important reason for the increased friction between the sole of the foot and the insole.

6. Customization (thermal shaping):

Semi-customization: Some insoles can be heated and softened in an oven, and then put on shoes to step on and shape them to get a contour that better fits the individual’s foot shape.

Full customization: Professionals scan or take molds of the foot to make insoles that fully fit the biomechanical characteristics of the individual’s foot. It can most accurately solve problems such as uneven pressure distribution and insufficient support, greatly reduce friction points, and has the best effect but the highest cost.

7. Antibacterial and deodorizing treatment:

Add silver ions, bamboo charcoal or other antibacterial agents to the material to inhibit the growth of bacteria and fungi, maintain hygiene, and prevent skin problems aggravated by infection.

3. Advice for football players on choosing insoles

1. Give priority to the combination of “shock absorption + support + perspiration + non-slip surface”:** For example, EVA or PU main body (provides cushioning and support base) + memory foam or silicone local reinforcement + moisture-wicking and antibacterial surface + non-slip bottom layer.

2. Pay attention to arch support: Choose a support strength that matches your arch type.

3. Thickness and shoe compartment space: Make sure that the thickened insole does not make your feet feel squeezed in the shoes, otherwise it will bring new friction points. You may need to choose a half-size larger shoe.

4. Try on and run-in: New insoles need a certain amount of time to run in. Use them for a short time in training first, and gradually increase the duration.

5. Socks: Choose professional, moisture-wicking, and smooth-seam (preferably seamless) football socks to work with insoles to reduce friction.

6. Consider customization: If the abrasion problem is serious and recurring, or if there are special foot problems (such as severe flat feet/high arches, old injuries, etc.), investing in a pair of professional customized insoles is often the most effective solution.

Summary

To alleviate the abrasion of the soles of football players, composite materials (such as partitioned EVA/PU+memory foam/silicone local+moisture wicking and antibacterial surface) combined with partitioned cushioning support, good arch support, breathable and perspiration-wicking design, seamless non-slip surface and non-slip bottom layer technology are the best choice. If the budget allows and the problem is serious, custom insoles can provide the most fundamental solution. At the same time, don’t forget to match professional football socks. Remember to confirm whether the thickness of the insole is suitable for your shoes before purchasing. The right equipment can make your feet more free on the court! ⚽

Tips: Before training or competition, apply Vaseline or use special sports anti-friction cream on the parts that are prone to abrasion, which can also form a protective film between the skin and socks to further reduce friction.

Every pair of insoles expresses the brand’s voice

I’ve been hearing lately that this factory has nothing to do, which factory has nothing to do? But is it really the case? But we’re